From Raw Material Selection to Finished Excellence: A Multi-Tiered Approach

At Alitan Corporation, quality is an engineered promise. Our ISO 9001:2015 certified facility embodies this commitment, with a comprehensive Quality Control Management (QCM) system meticulously integrated into every production stage.

Our dedication to QCM extends beyond individual techniques. We foster a culture that prioritizes:

Cross-Functional Collaboration

Open communication and collaboration between departments ensure seamless integration of QCM practices throughout Alitan Corporation’s production.

Advanced QCM Software Integration

We utilize state-of-the-art QCM software for data collection, analysis, and real-time quality monitoring.

Investment in Training and Development

We invest in ongoing training for our QCM team, ensuring they possess the latest knowledge and expertise in quality control methodologies.

Statistical Process Control (SPC)

Alitan Corporation utilizes SPC methodologies to monitor key production parameters, ensuring consistent quality and minimizing variability.

Defect Prevention at its Core

Our QCM system prioritizes defect prevention through proactive measures at each stage of the process.

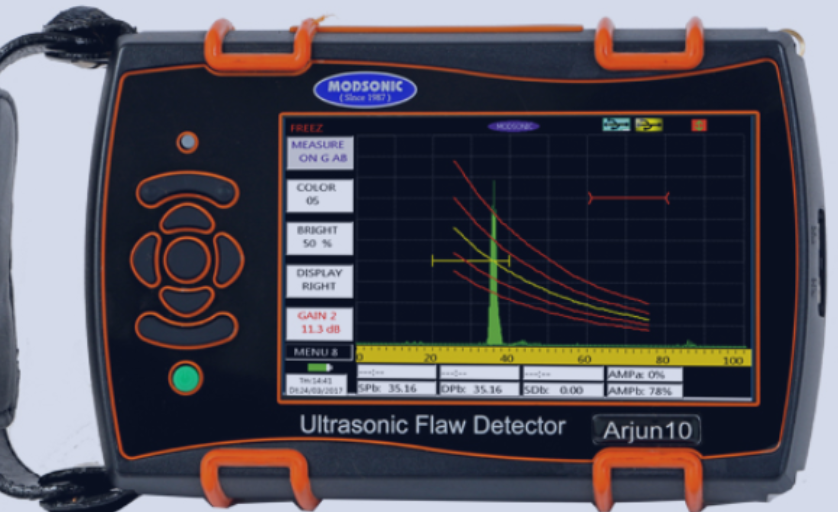

Non-Destructive Testing (NDT)

We employ a range of NDT techniques to assess leather characteristics without compromising the material. This allows for in-depth quality evaluation throughout Alitan Corporation’s production process.

Continuous Improvement Through Measurement

We leverage data collected through rigorous inspections and testing to continually refine Alitan Corporation’s QCM processes for optimal performance.